Our Achievements & Innovations

Hewitt Robins International has a wealth of history, design and innovtions over the years.

Conceived in 1891 Thomas Robins, founder of Hewitt Robins began devising the first innovative belt conveyors.

First vibrating screen designed by Thomas Robins, founder of Hewitt Robins International.

"Circle-throw", uniform motion screen.

High-speed mechanical screen, oil lubricated, with variable stroke.

In 1935 Hewitt Robins supplied the largest shakeout in the world! This Hewitt Robins 12m x 8m Heavy Duty Foundry Shakeout deck consisted of 6 individual shakeout frames handling a combined deck load of 60 ton.

Elliptical stroke, horizontal screen.

"Slip-fit-on-the-shaft" unitized bearing flange assembly

Start-Stop bounce restrictor, floating and friction type.

Parallel wire dewatering screen.

Heavy-duty, two-bearing screens and scalpers

High-strength torqued boiling system

Electrical strain gauge, stress-coat and photoelastic stress measurement in design analysis

Eight-bearing, four-shaft vibrator

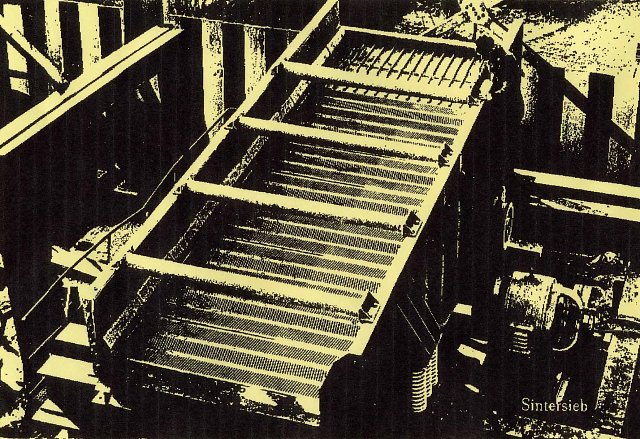

Special-Duty (1400 F) Hot Sinter Screen

Screen cloth tension wedge.

Vari-grid grizzly 7' and 8' wide, and 20' long two-bearing screens

Back in the 1960's Hewitt Robins designed and produced Mobile Washing & Screening Plants called 'Washmore'. These plants came in three sizes to handle either 60 cu.m/h, 100 cu.m/h or 150 cu.m/h. The plants consisted of twin axel frame, revolving scrubber, a three-deck washing screen, and screw conveyor.

Parallel rod deck with zipper-type attachment

Analytical analysis of "off-motion" phenomenon

X-brace cross-members for a more rigid vibrating frame.

Self-supporting perforated and solid deck panels for shakeouts and screens.

In 1967 Hewitt Robins supplied 16 Screens to a major steel plant in Sweden. This picture shows four 2E13 2.5m x 8m Double Deck Low Angle Screens which are still in operation today.

Super-duty (200 F) hot sinter briquette screen

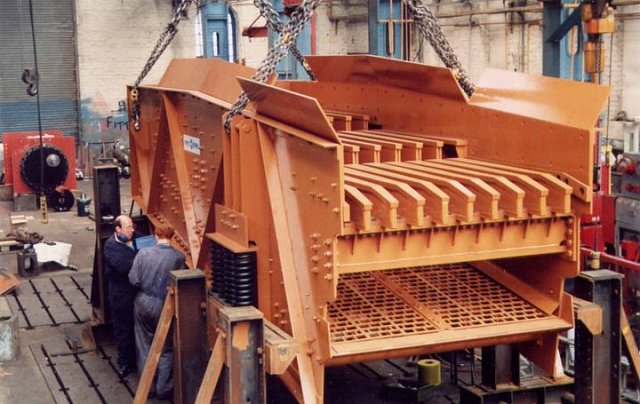

Twelve-bearing, six-shaft vibrator capable of vibrating 50-ton unit with 1/2 stroke at 700 RPM to provide 6000 TPH scalping capacity.

Quick wedge clamp system for attaching cloth support bars to crossmembers.

Tubular cross member bars (adds strength in all directions)

Double VIBREX (Two synchronised vibrators for increased stroke and bearing life)

Vibrating no-bake foundry sand reclaimer

Triple deck 10ft by 24ft developed for high volume screen applications. Many configurations now available.

Back in 1985, this advert was placed in a leading mining publication.

In 1988 Hewitt Robins supplied four Low Angle Screens for a dredger in the Netherlands. These machines were handling a combined feed of 700tph of dredged material, which was washed on the first two Horizontal wash screens. The sand was dewatered on the final two dewatering screens at a combined feed rate of 500tph to allow it to be dry enough to be conveyed to shore.

Hewitt Robins factory in Glasgow, busy getting 12 horizontal screens ready to export for the Dam project in Pakistan.

Development of High Energy Screen with G-Force up to 6.5G for problematic, difficult to screen materials

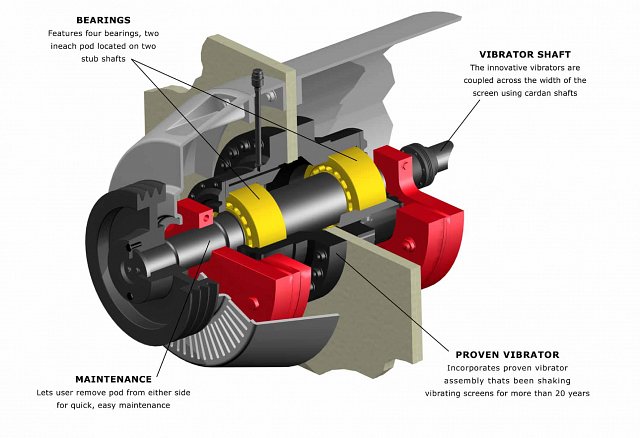

2 Bearing Vibrator Pod called the Quad- Unit designed for easy maintenance and increased bearing life.

In 1995, this Hewitt Robins 2E13 2.5m wide x 7.5m long Extra Heavy Duty Double Deck Grizzly Scalper was going through the workshop in Glasgow. This monster was handling 3000tph of -1.5m lumps of limestone and was scalping out at 200mm on top deck using grizzly bars and 40mm on the bottom deck using a punched plate.

Designed and developed widescreens up to 3.6m in width and 10m in length incorporating the Quad-V Vibrator Unit

Following the takeover of W.S. Tyler, the British management team acquired the remaining shares in the company to become sole owners of Hewitt Robins International Ltd.

Hewitt Robins develop a modular plant design incorporating screens, feeders and crushers for complete plant set up.

Wheel mounted mobile crushing and screening plants commissioned and installed worldwide

Back in 2010, Hewitt Robins supplied a replacement 2.5m wide x 6.0m long Double Deck Iron Ore Screen for a Steel plant in Venezuela. This Hewitt Robins screen was handling 1200tph of Iron Ore and the original Hewitt Robins screen was in operation since 1972.

Hewitt Robins was acquired by Tata to implement Hewitt Robins design into the Indian market and use their the huge experience and knowledge.

Self-Synchronised 2QV vibrator unit to produce linear motion screening without timing belts or gears.

The design of the biggest, heaviest duty shakeout in the world handling a total deck load of 160ton.

Celebrating 130 years of trading.